DeepWater Buoyancy is the world’s largest producer of subsea buoyancy products for the oceanographic community. At the heart of the product line are the deployment solutions for ADCP applications, including spherical and elliptical buoys, the low-drag StableMoor® buoy, trawl-resistant bottom mounts (TRBMs) and diver serviceable bottom mounts.

This article will spotlight DeepWater Buoyancy’s frame designs for ADCP buoys.

For more information, click HERE.

In the early days of acoustic doppler current profilers (ADCPs) most units on the market were designed with four transducer beams. To most effectively accommodate these four-beam ADCPs, buoys were produced with four tie-rods that pass through the buoy and end frames with four legs that attach to the tie-rods. This design allowed for the beams of the ADCP to pass between the frame legs, unobscured.

Advances in ADCP technology have since led to ADCPs with as few as three beams and as many as nine transducer beams. In some cases, a center (vertical) beam is included in the configuration. These technological advances in ADCP design have led to changes in the design of the framework for ADCP buoys.

ADCPs with various transducer configurations.

In the case of a three-beam ADCP, buoys are now offered with three tie-rods and end frames with three legs that pass between the beams. For customers who have previously purchased a buoy outfitted for a four-beam ADCP, but now look to use a three-beam ADCP, a frame is available that mounts on the four tie-rods and transitions to three legs to pass between the beams. Additionally, a buoy can be outfitted with a four-beam frame on one end and a three-beam frame on the other for compatibility with both systems.

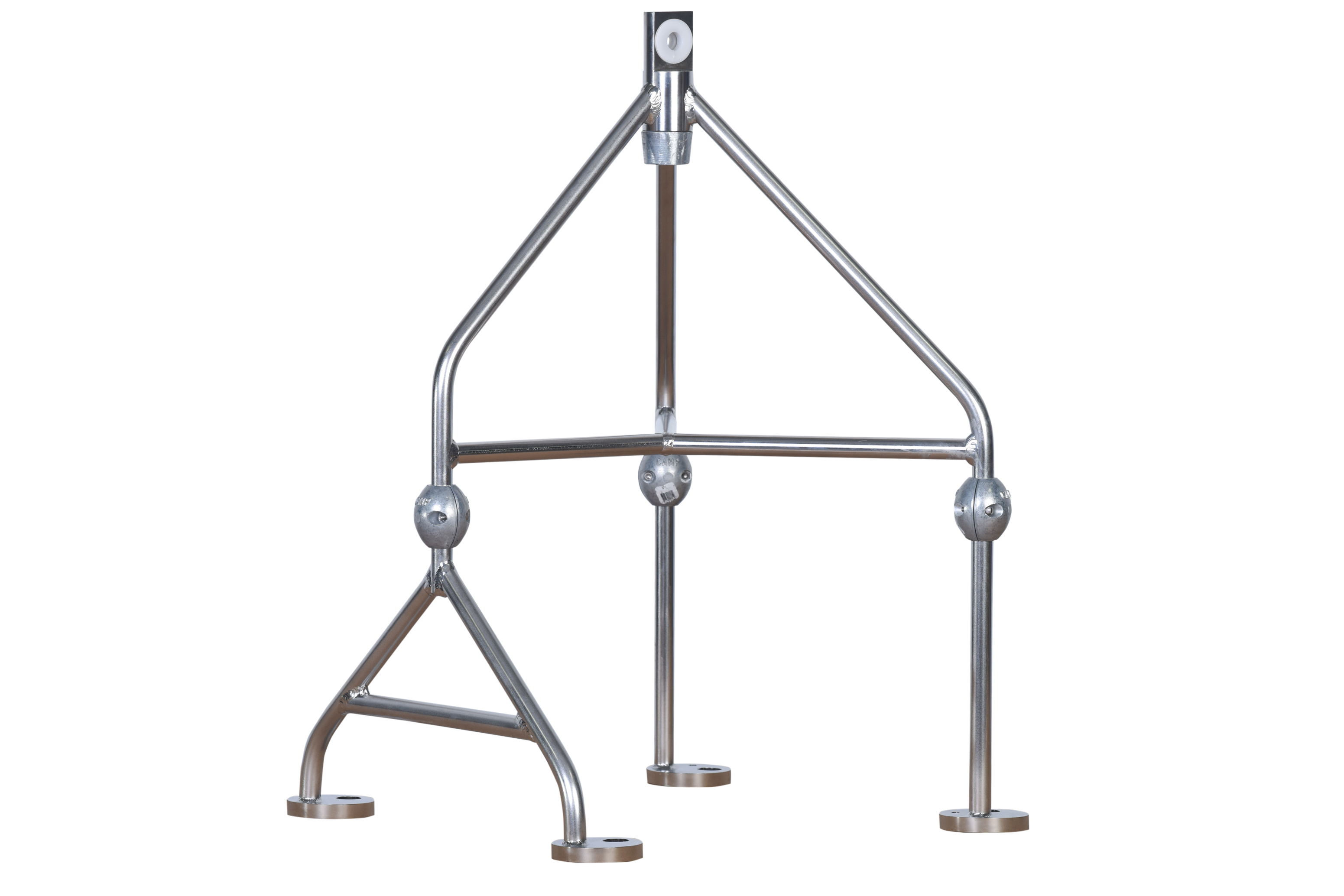

ADCP Buoy Top Frame made for a 3 beam ADCP to be mounted in a buoy with four tie-rods.

When a buoy is at the top of a mooring and a vertical beam is used, or when an ADCP with several beams is used, typical frames would block the beam or beams. And since the buoy is at the top of the mooring string, the need for a top arbor is eliminated. In this case a ring frame is used. This frame serves to protect the ADCP head during deployment, recovery, and handling on the deck of a vessel, but will not obstruct the beam pattern.

Ring Frame for ADCP with center vertical beam.

All frames are manufactured with 316L stainless steel. The frames are then electropolished and fitted with replaceable zinc anodes for superior corrosion resistance. Frames with arbors on them are fitted with isolation bushings and allow connection to the mooring line with standard shackles.

Our extensive in-house design, machining, metalworking, and welding capabilities allow us to make an endless variety of these frames to support and protect not only ADCPs, but also a wide range of other instrumentation. DeepWater Buoyancy’s engineering staff will work with you to design the exact frame that best meets the needs of your equipment, pass through loads, and time at depth.

About DeepWater Buoyancy, Inc.

DeepWater Buoyancy creates subsea buoyancy products for leading companies in the oceanographic, seismic, survey, military and offshore oil & gas markets. Customers have relied on our products for over thirty-five years, from the ocean surface to depths exceeding six thousand meters.

Learn more at www.DeepWaterBuoyancy.com