In Print – Maine International Trade Center GlobalView

DeepWater Buoyancy was chosen as the lead story for this quarter’s edition of Maine International Trade Center’s GlobalView Newsletter.

The Maine International Trade Center visited the DeepWater Buoyancy facility and interviewed our Director of Business Development, David Capotosto

See the whole newsletter HERE.

MAINE IS INTERNATIONAL: Focus on Biddeford-Saco

As a statewide organization, Maine International Trade Center (MITC) has internationally engaged members located in all 16 counties that include manufacturers, service providers, and educational institutions. This article is the first in a series that will explore the diversity and dynamism of Maine’s international community through profiles of our members and economic development partners across the state.

The Biddeford-Saco region is experiencing significant economic growth. With over $200 million of investment in recent years, the once abandoned Mill District is the center of activity with over 150 businesses. Located in York County, these twin communities are the sixth (Biddeford) and eighth (Saco) largest cities in Maine. Here’s a look at what international means to three MITC members in the region.

DeepWater Buoyancy

When people ask David Capotosto what his Biddeford company does, his answer might sound confusing.

“I say we make stuff that floats underwater,” says Capotosto, Co-President and Director of Business Development at DeepWater Buoyancy. “Anyone that wants to put something heavy under the ocean and get it back someday probably needs us.”

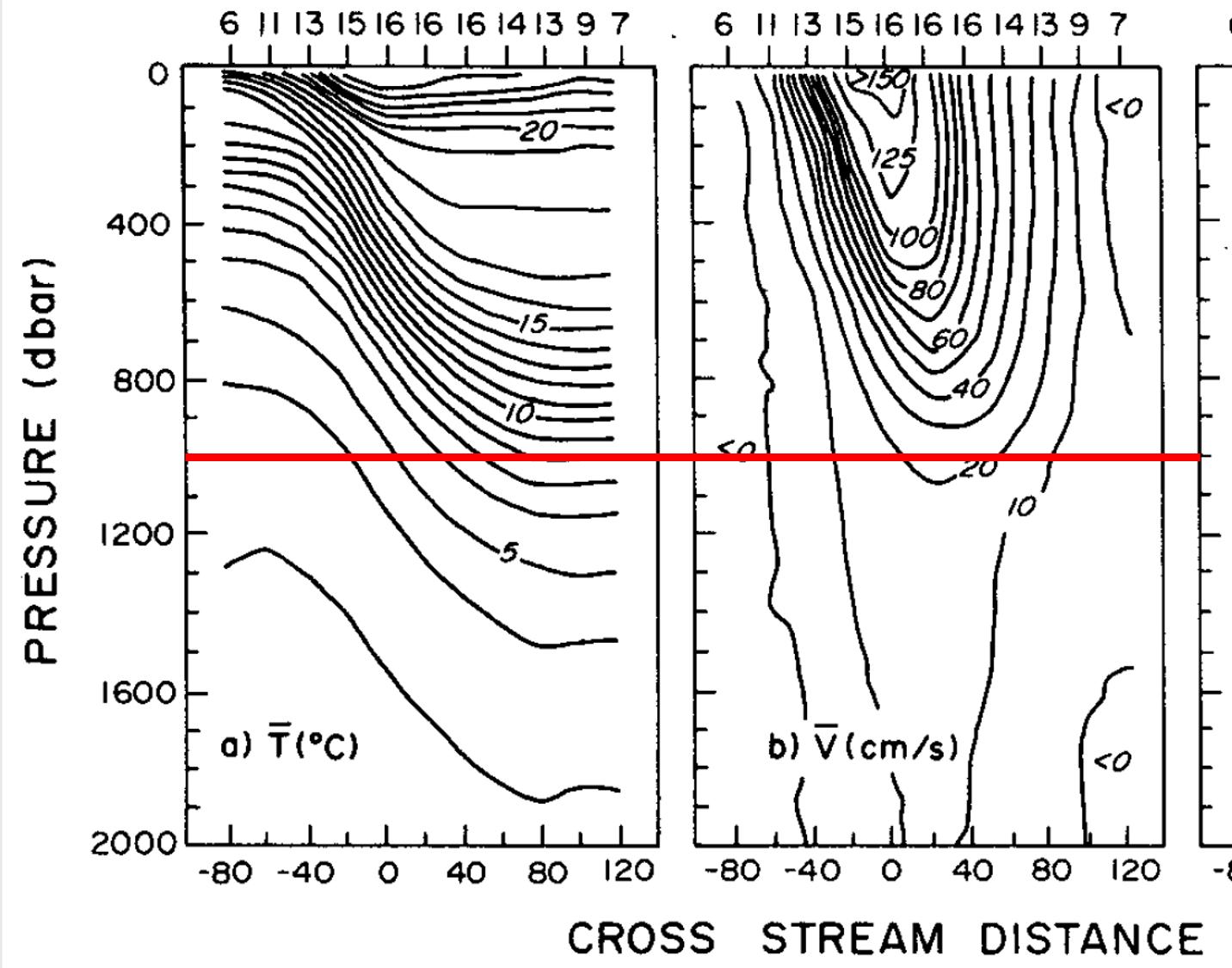

“Let’s say you want to study ocean currents, or you want to look at the long-term effects of PH in deep sub-sea,” continues Capotosto.

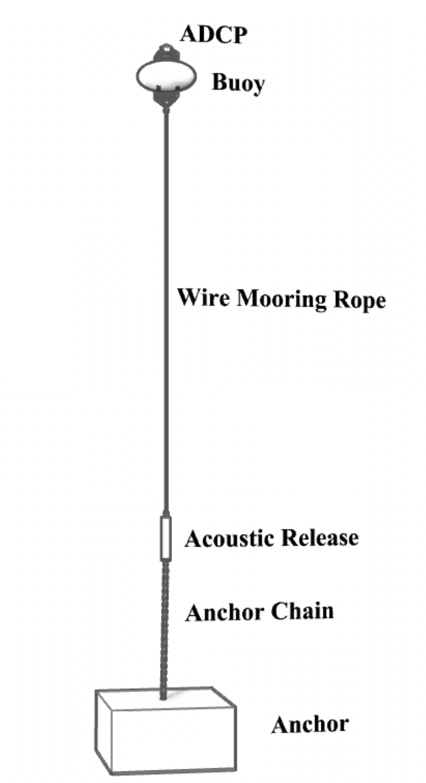

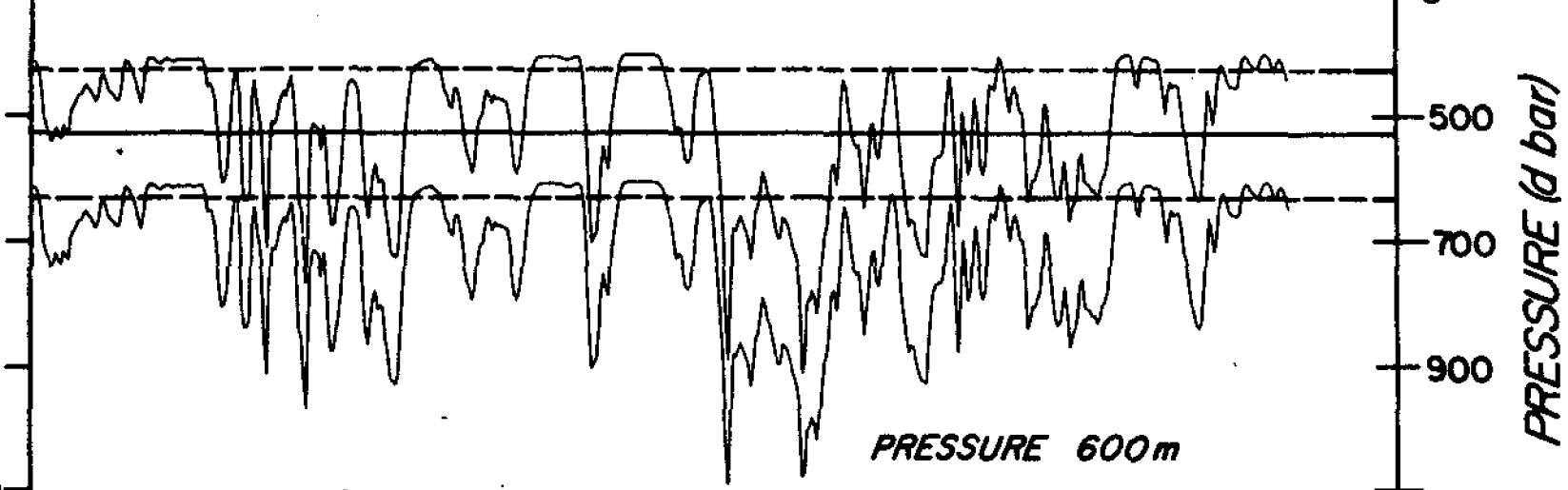

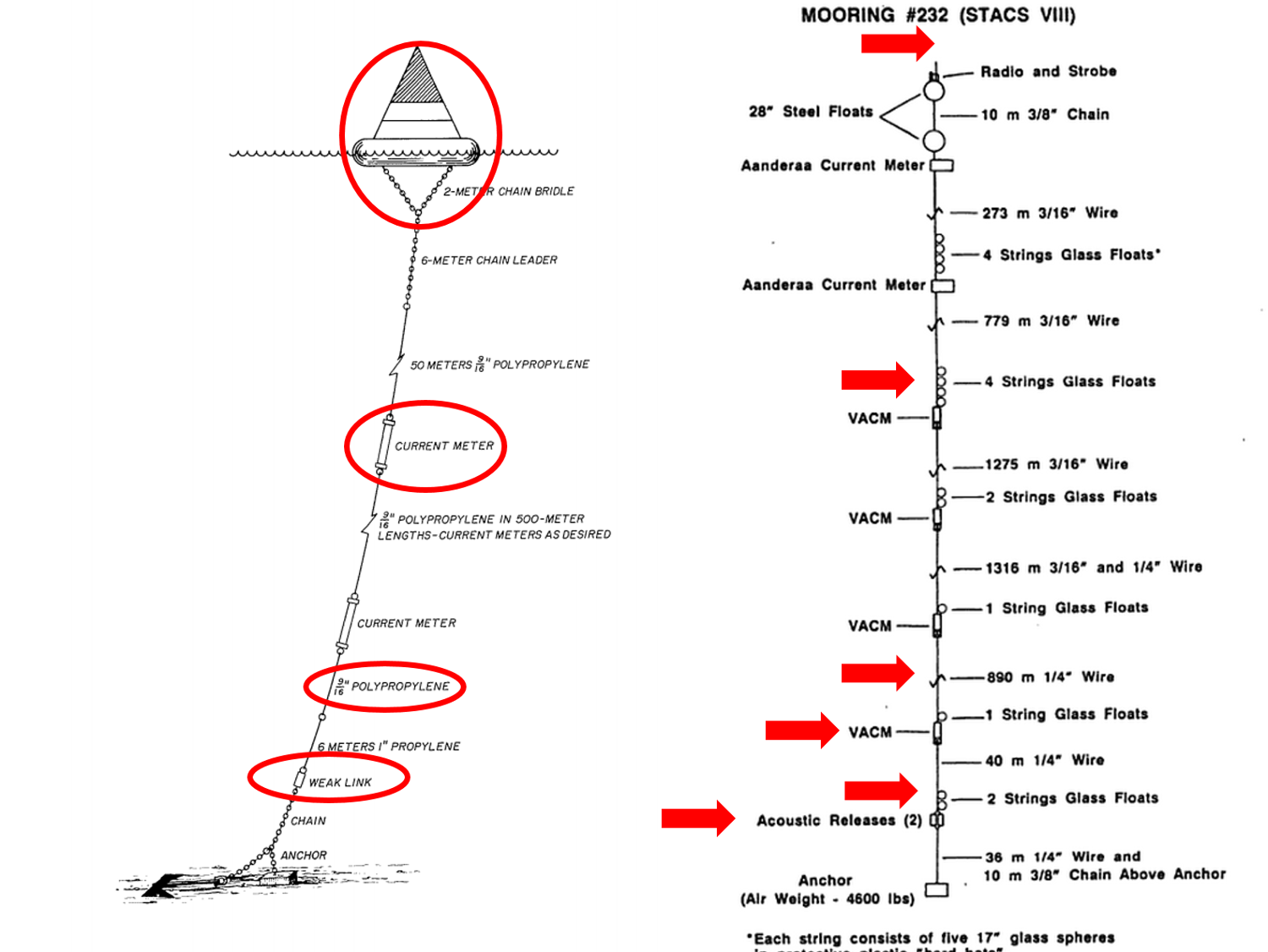

For such research, monitoring equipment must be placed on the sea floor beneath thousands of meters of water to collect data for some period of time and then later brought back to the surface.

DeepWater Buoyancy designs, engineers, and manufactures buoys that are sent off a boat with the measuring instruments and a heavy weight that sinks everything to the bottom. When it’s time to recover the mooring, an acoustic signal is sent to the equipment telling it to detach from the weight, and the buoy floats to the surface bringing the instruments and data with it. The company is the worldwide leader in underwater buoyancy for the oceanographic community.

About 35% of what they produce leaves the country. The UK and China have been two strong markets, although Capotosto noted that the last round of China retaliatory trade tariffs will affect the landed cost of the buoys.

DeepWater Buoyancy was formed in 2013, but the product they make has been around for close to 40 years. Founded in 1979 as Flotation Technologies, the company was family run for many years then sold to larger companies out-of-state. Now, 4 former employees of Flotation Technologies own the new company, and many of the 22 employees have actually worked together for decades.

The company has been selling internationally for many years and seeks out Maine International Trade Center for guidance on workforce development, market research, export controls, and grant assistance.

“We’re buoyancy specialists, not grant specialists, so having access to people who know about the grant world and the other resources at MITC, instead of creating it all in-house, makes sense for us,” said Capotosto.

The company anticipates significant growth in the next 5 years which includes launching new products, expanding into new markets, making capital investments, and hiring more people. Growth that is exciting, yet also measured.

“Strategically, we take a conservative approach because we want sustainable success for everyone,” says Capotosto. “We want this to be around for the children of our employees should we be so blessed and fortunate to have our markets remain strong.”

About DeepWater Buoyancy, Inc.

DeepWater Buoyancy creates subsea buoyancy products for leading companies in the oceanographic, seismic, survey, military and offshore oil & gas markets. Customers have relied on our products for over thirty-five years, from the ocean surface to depths exceeding six thousand meters.

Learn more at www.DeepWaterBuoyancy.com

About Maine International Trade Center

Maine International Trade Center (MITC) helps Maine businesses enter and expand global markets for their products and services. MITC offers one-on-one consulting and research, affordable group trade show participation, connections around the world, export reimbursement funds for small businesses, and more. Leveraging overseas synergy, MITC also works to increase international student attraction and foreign investment. A public-private partnership, MITC is funded through Maine Department of Economic and Community Development (DECD), corporate contributions, and membership dues of nearly 300 businesses and organizations.

MITC members include manufacturers and service providers, economic development and government agencies, educational institutions, and trade assistance organizations. We work with both exporters and importers.

Learn more at www.mitc.com/